P R O D U C T S

|

|

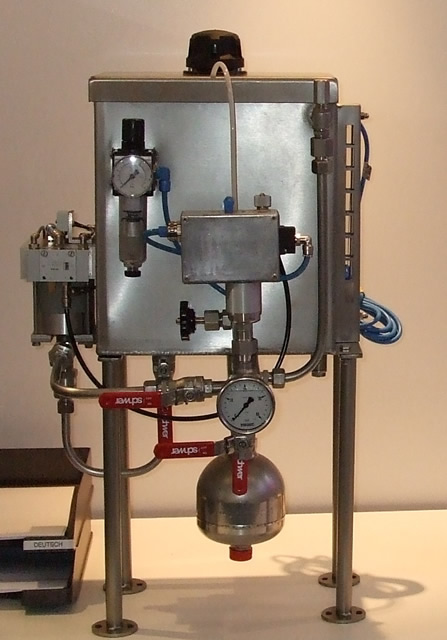

A. Hand operated pressure - unit for 1-2 mech. of GLRD seals

|

|

A1

|

A2

|

A3

|

A4

|

|

SPH 2300 for 1-2 mech. seals. max. 40 bar

|

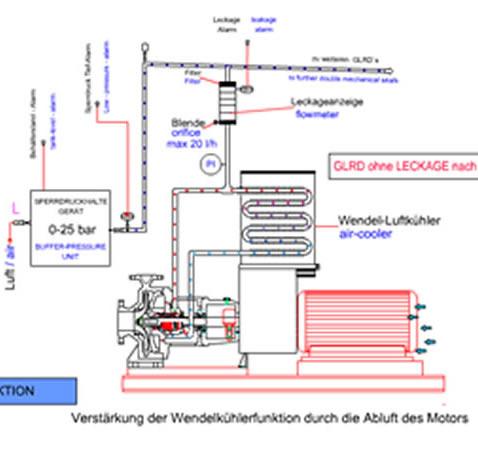

SPH 2300, with air cooler 400-1200 Watt +circulation pump MP 2100 with magnetic drive

|

SPH 2300 mounted on base plate, with air-cooler, mech. seal with pumping device. About 100 units are already working at EVONIK and BASF - Antwerp

|

Animation / function of a SPH 2400

|

| |

|

______________________________________________________

B. Central Pressure units for up to 20 mech. seals

|

B1

|

B2

|

B3

|

|

|

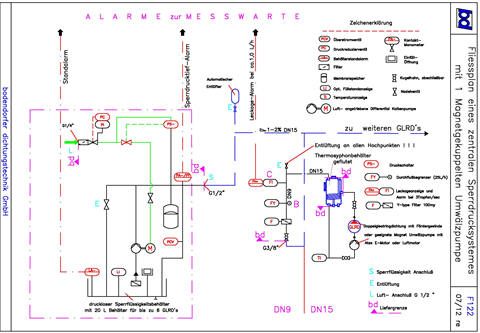

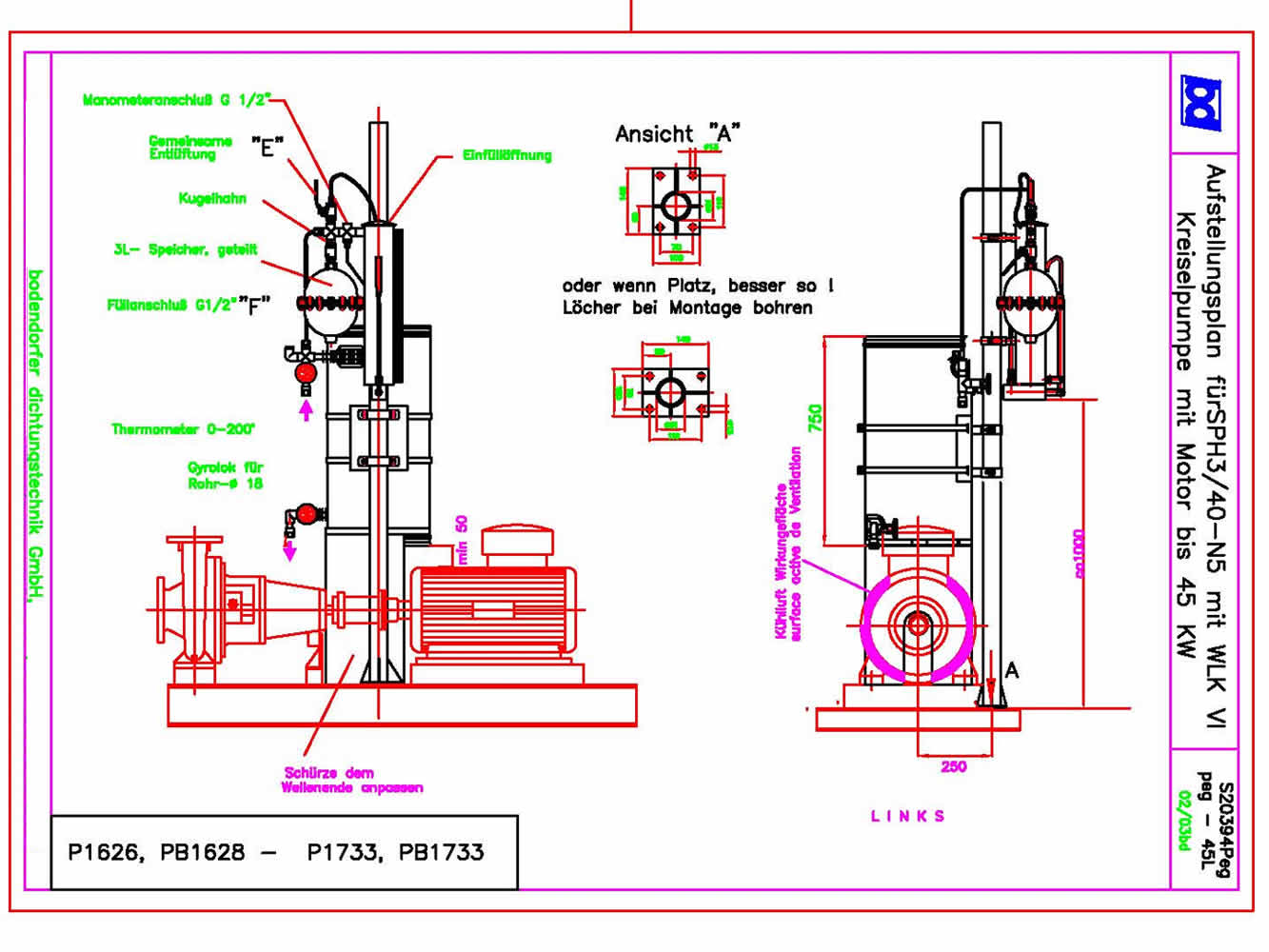

Flow plan for a pressure unit with 1 diff. piston pump for up to 4 connected mech. seals

|

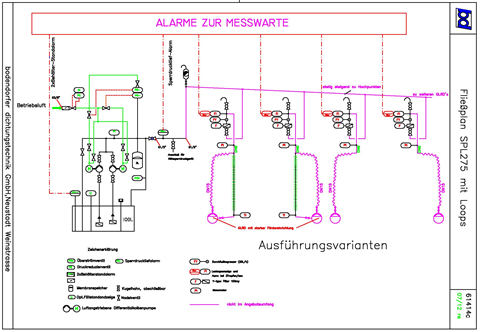

Flow plan for automatic pressure units with 2 differential piston pumps M2100 for up to 6, 10 or 20 connected mech. seals

|

Animation/Function of an automatic central pressure unit with air- cooler, flow meter + orifice, mounted on a centrifugal pump with pumping device.

|

|

|

B4

|

B5

|

B6

|

B7

|

|

SPGD122 for max.5 mech. seals, pressure unit with 1 air driven differential piston Pump and 22 L container for pressure less barrage- liquid, with level alarm and connection G1/2 " for pressure Alarm by customer, up to 35 bar.

|

SPG 260 for max 10 mech. seals, with 2 pneum. driven differential piston pumps, with 60 L container, for pressure less buffer-fluid, with level and buffer pressure alarm up to 60 bar

|

SPL 2100 for 2 buffer pressures, for max. 20 mech. seals with 2 pneum. driven differential piston pumps M2100, with 200 L container for pressureless buffer- fluid with level and pressure alarm up to 60bar

|

SPL 2200 for max 20 mech. seals with 2 pneum. driven differential piston pumps, M2100 with 200 L container for pressure less buffer- fluid with level and pressure alarm and up to 30 mech. seals

|

Rest follows:

- All is in Execution Ex-1, ATEX and Stainless steel

|

|

______________________________________________________

C. Air coolers (maintenance-free) and Water coolers (low-maintenance)

|

C1

|

C2

|

C3

|

C4

|

|

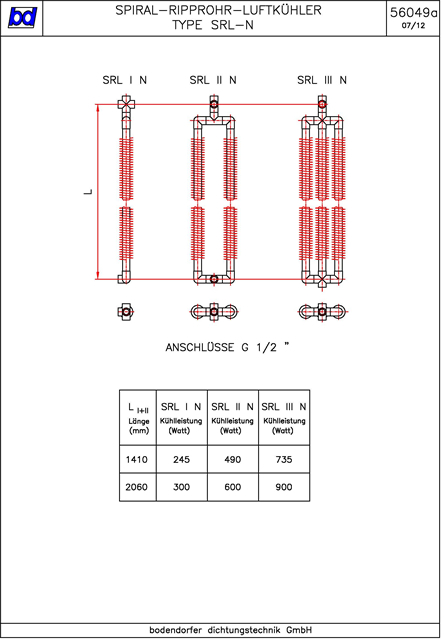

range of rod Air coolers up to 1200Watts

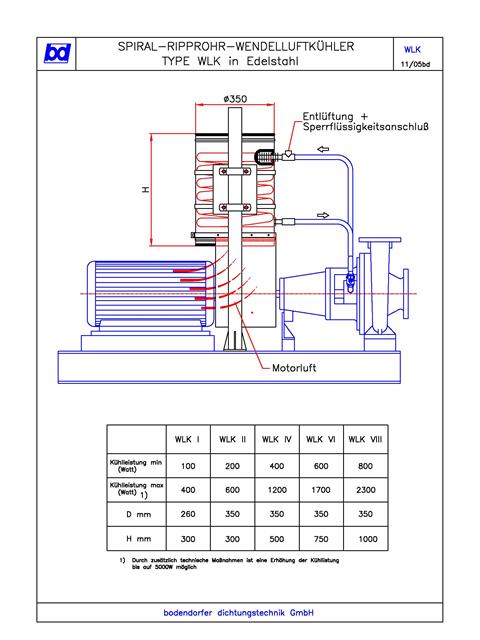

|

range of helix air coolers up to 5000 Watts

|

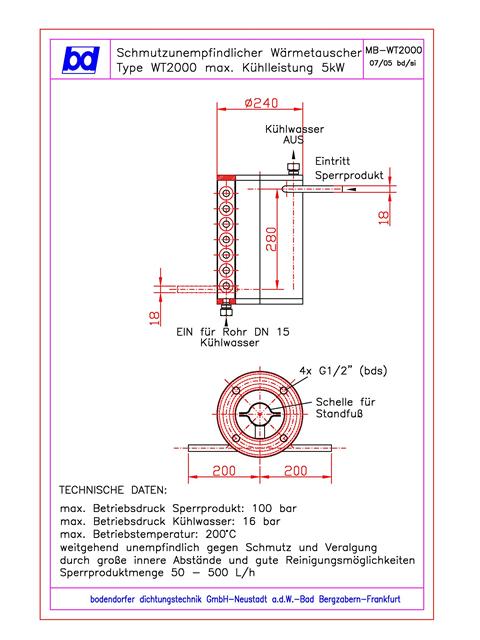

River water cooler WT 6000 up to 6000 Watts, can be cooled by river water and cleaned with acid without having to be dismantled.

|

Photo of water- cooler WT6000 |

|

|

|

|

|

______________________________________________________

D. ALARMS and SECURTY - features

|

|

D1

|

D2

|

D3

|

D4

|

|

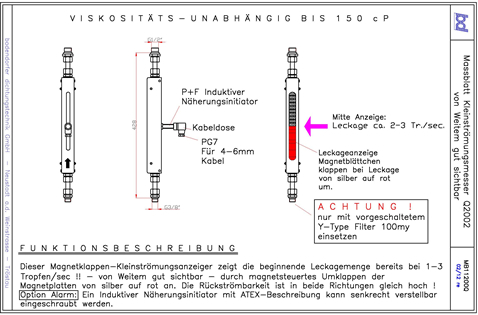

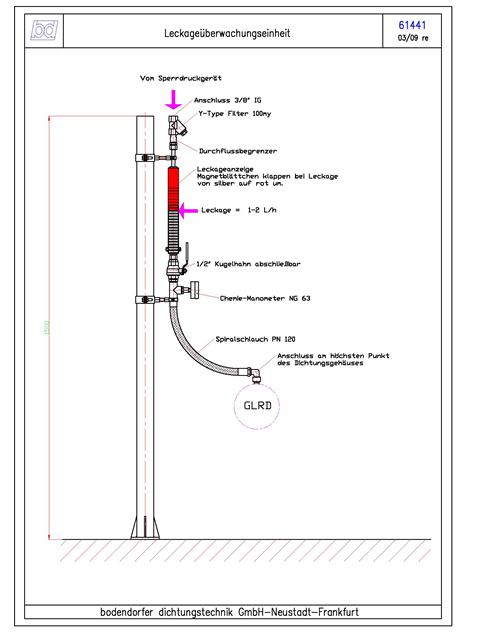

Flowmeter Q2000, for leakage - alarm at 1 L/h leakage into the pump and / or to the atmosphere, 1drop = 1 silver plate turns to red.

|

Dead - End connection of a mech. seal. with flow meter Q2000

|

Orifice in front of every seal protect the other seals.

|

Tank level device. Level of the tank is very good to see with blue glass float indicator in protected glass pipe.

|

|

|

|

|

|

______________________________________________________

E. Accessories

|

|

E1

|

E2

|

E3

|

|

|

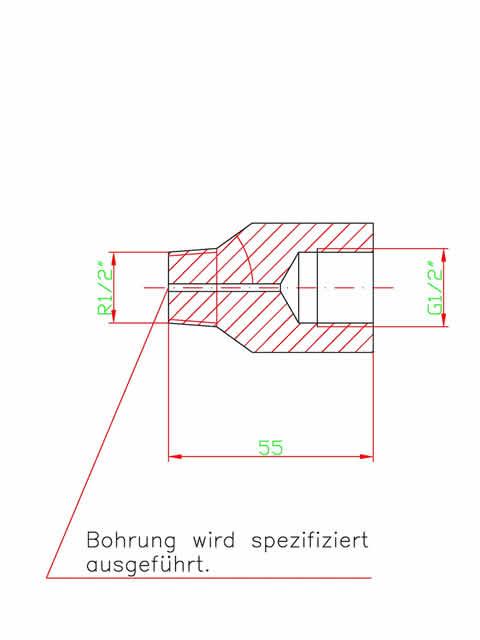

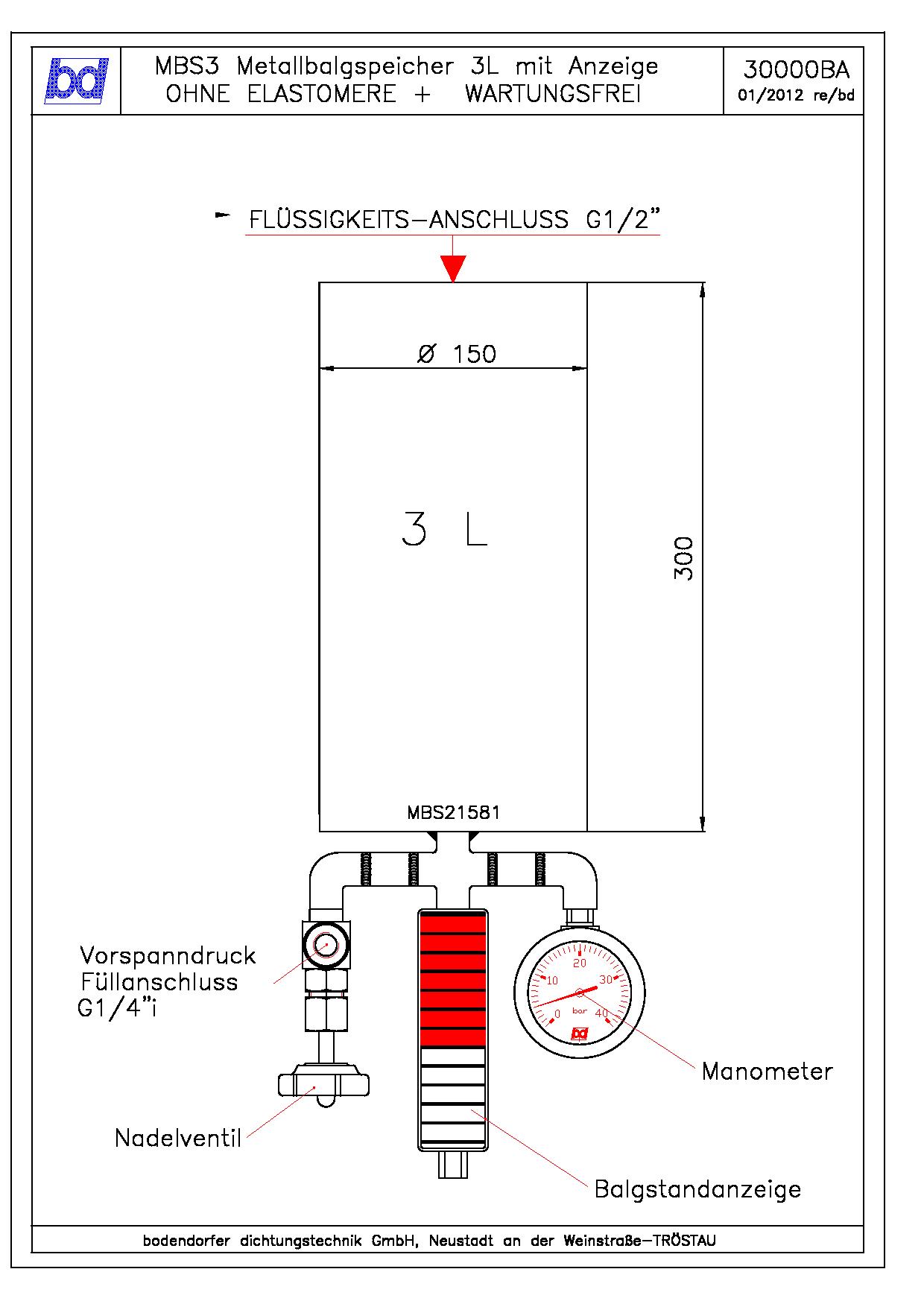

worldwide innovation: accumulator MBS all in s.s. (without elastomers) 35 bar, 200 °C maintanance free, with connectin for preset pressure

|

MBS dimension drawing |

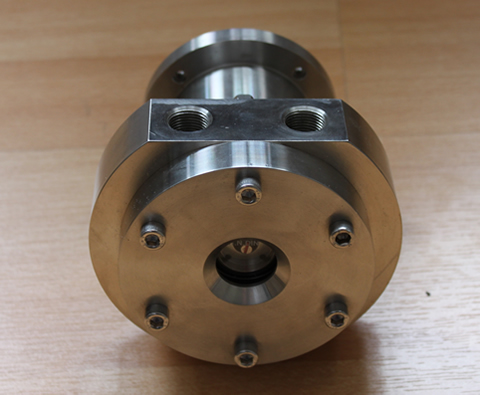

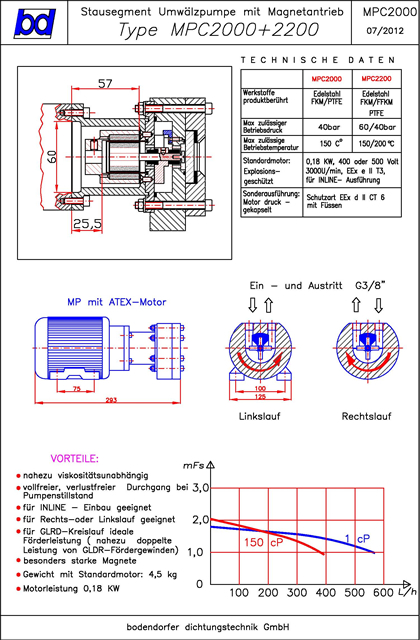

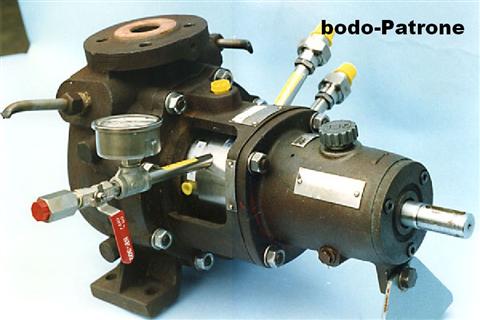

circulation pump type MPC with magnetic drive Ex 1, until 60 bar, until 150 cP

|

|

|

|

|

|

|

E4

|

E5

|

|

|

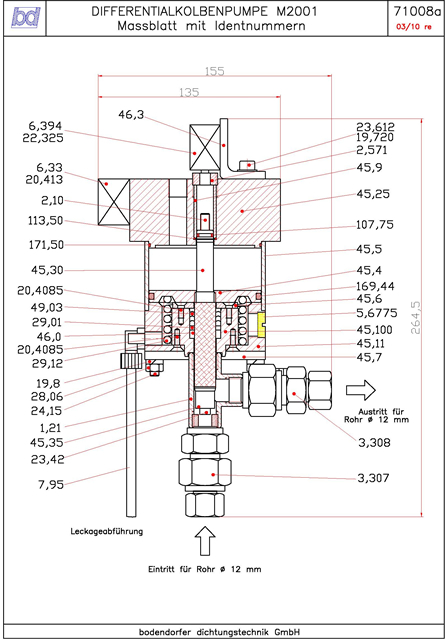

|

air driven differential piston pump M2001, 1:20 with only 3 O-rings in FKM(in FFKM possible) max. pressure 60 bar

|

Magnetic drive circulation pump MP2001 with Ex-motor 0,2 KW for all kinds of buffer - fluids up to 150 cP, 6o bar , with high capacity.

See techn. Sheet,The head of the pump is more than twice x higher than mech. seal pumping devices, also at viscos buffer-fluids).

|

|

|

|

|

|

|

|

______________________________________________________

F. Filter

|

|

F1

|

F2

|

F3

|

|

|

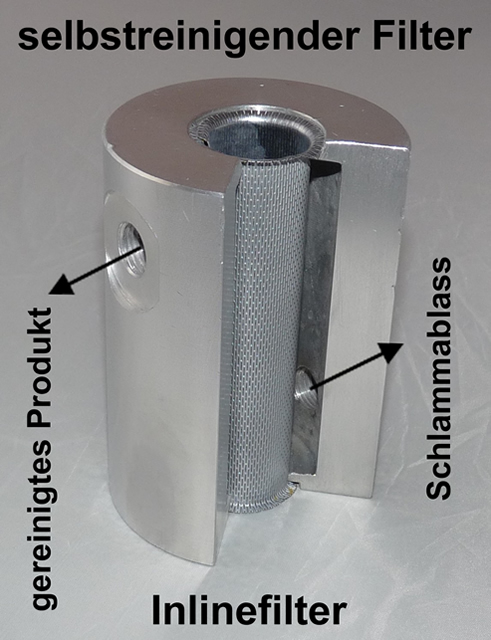

Self-cleaning filter type SRP for nuclear pumps.

|

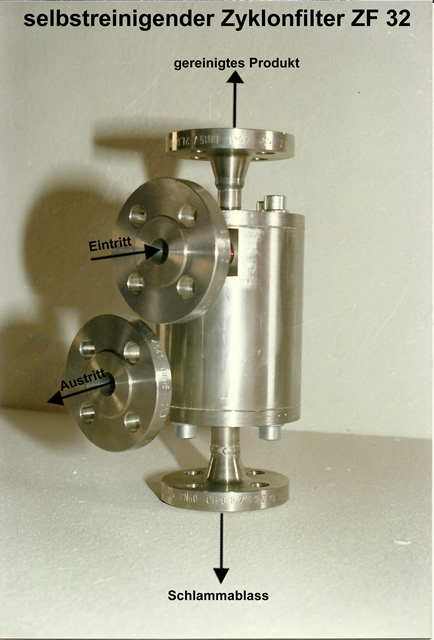

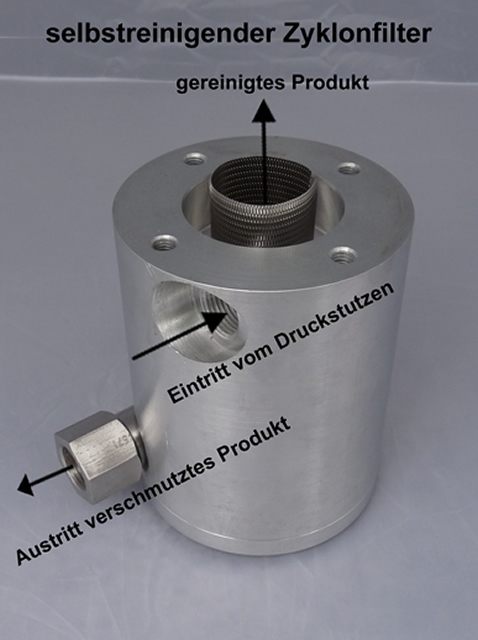

Self cleaning Filters type ZF extern situated, with flanges or fittings

|

Self cleaning Filters type ZF extern situated, with flanges or fittings

|

|

|

|

|

|

|

F4

|

F5

|

|

|

|

Self cleaning Filters for the discharge of PUMPS.

|

Self cleaning Filters type ZF extern situated, with flanges or fittings

|

|

|

|

|

|

|

|

______________________________________________________

G. Photos of executed units in the chemical industry and oil refinery

|

G1

|

G2

|

G3

|

G4

|

|

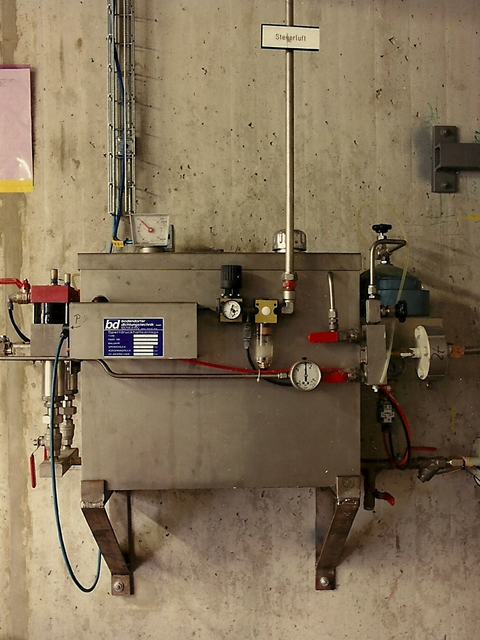

SPL 275 in petro- oil plant with 4 flow-meters directly mounted on the pressure station.

|

first (1984) test pressure unit SPL 290 with automatic tank level supply.

|

Automatic Temperature-regulation of buffer fluid between 180°C and 200 °C with TIC and MP2000

|

Hand operated SPH2001 with air cooler running delivered 120 x to EVONIK Antwerp.

|

|

|

|

|

|

|

G5

|

G6

|

G7

|

G8

|

|

SPL 275 with15 refinery pumps with a big air cooler in a large oil-refinery

|

5 x MP2000 circulation pumps at BASF-reactor.

|

Air cooler at multi - stage KSB-pump in a power- station in Milano, Italy.

|

significant running time of the double seals by connecting the pressure containers and mechanical seals direct to our pressure - units.(changing of pressure - gas to buffer fluid)

|

|

|

|

|

|

______________________________________________________

|

|

G1

|

|

|

|

|

NEW!

idea for an optimal double mech. seal

>>> Detail

|

|

|

|